Paul,I assume that’s a lower modulus rod than Tim is bending - out of interest how heavy is the weight?

I think that in most cases stiffer high modulus materials will tend to have lower strain failure limits. Merlin probably has more up to date values but I think the strain limit for graphite rods is around 2% while it is around 6% for fiberglass rods.

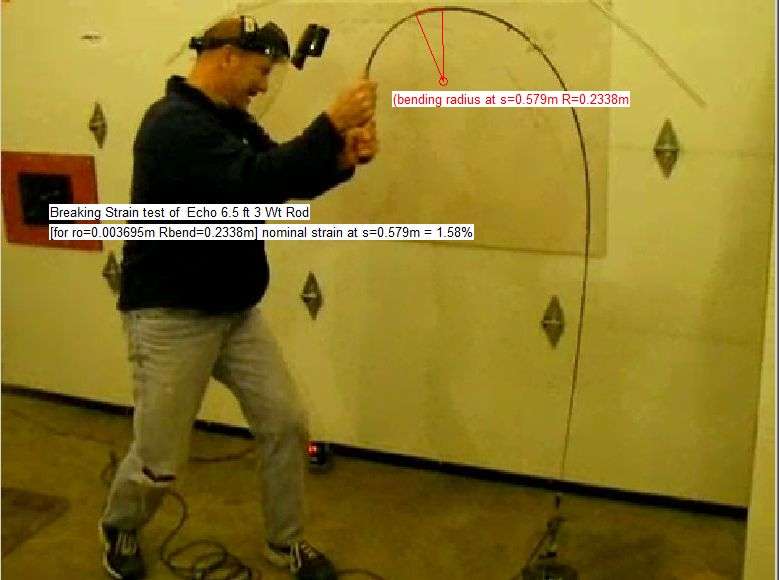

The rod in that photo was a 6.5 foot 3 wt. It took a fork lift to break a 10 wt. rod.

Gordy