PLEASE NOTE: In order to post on the Board you need to have registered. To register please email paul@sexyloops.com including your real name and username. Registration takes less than 24hrs, unless Paul is fishing deep in the jungle!

Fly Line Stretch and Viscoelasticity

Moderator: Torsten

Fly Line Stretch and Viscoelasticity

Motivation

Bernd has written a nice front page about "Fly Line Stretch"

https://www.sexyloops.com/index.php/ps/fly-line-stretch

and we had already a in-depth discussion at the tackle section here:

https://www.sexyloops.co.uk/theboard/vi ... =18&t=3622

Some fly line companies claim indeed that low-stretch fly lines have several advantages, but to my knowledge no objective studies exist that would prove these claims.

See for instance:

Tim Rajeff explains barstool Line low stretch technology

RIO InTouch Lines with ConnectCore

So I thought it makes sense to create a topic also here in the physics section, where we can collect ideas for measuring fly lines, equations and models. When we have enough information gathered, we should be able to check the plausibility of the above mentioned supposed advantages. Also when we have measured these properties we can insert them into existing fly line models to make them more realistic.

We can find most definitions/equations on Wikipedia, so I'll link/cite these pages.

Properties to characterize fly line stretch

A simple model for the fly line would be a linear spring and stiffness is usually employed to describe their behaviour:

From https://en.wikipedia.org/wiki/Stiffness

"The stiffness, \(k\) of a body is a measure of the resistance offered by an elastic body to deformation."

\(k = \frac {F}{\delta}\)

where

\(F\) is force on the body and

\(\delta\) is the displacement.

Measuring stiffness of a fly line at home:

(1) Mark a section of a fly line at a distance of 1m e.g. with a china marker

(2) Take several test weights and measure the elongation of the fly line between the markers

\(l1\) = 1m

\(l2\) = your measured value

\(k = \frac{m_{test} * 9.81 \frac{m}{s²}}{l_2 - l_1}\)

The guys from the German fly fishing forum used always a 1,8 kg test weight. Here are some of their findings (German term "Dehnungswerte" in the reviews):

https://www.fliegenfischer-forum.de/flischnu.html

Example 5% @ 1,8kg

\(l2 = 1.05m @ 1,8kg\)

\(k = 1.8kg * 9.81 \frac{m}{s²} / (1.1m - 1m) = 353.16N/m\)

Relationship to elasticity

Another possible property would be the elastic modulus (of the fly line material).

https://en.wikipedia.org/wiki/Elastic_modulus

"An elastic modulus (also known as modulus of elasticity) is a quantity that measures an object or substance's resistance to being deformed elastically (i.e., non-permanently) when a stress is applied to it."

https://en.wikipedia.org/wiki/Stiffness

"The elastic modulus of a material is not the same as the stiffness of a component made from that material. Elastic modulus is a property of the constituent material; stiffness is a property of a structure or component of a structure, and hence it is dependent upon various physical dimensions that describe that component. That is, the modulus is an intensive property of the material; stiffness, on the other hand, is an extensive property of the solid body that is dependent on the material and its shape and boundary conditions."

If you know the cross-sectional area, you can compute the elastic modulus from the following equation:

\(E = k * L / A\)

\(A\) is the cross-sectional area

\(L\) is the length of the object

for above example, if we assume a fly line diameter of 1mm:

\(A = \pi * r²\) where r is the fly line radius, thus

\(E = \frac{353,16 N/m * 1m}{\pi * (0.001m / 2)²} = 401274175 N/m² = 0.4 GPa\)

The slight challenge is here, that a fly line consists of multiple materials; the core has a different elastic modulus than the coating. You could assume an average cross-sectional area, but I'd say that choosing the stiffness@1m as property makes more sense.

Viscoelasticity / Damping

Here you will find a good introduction to this topic:

https://www.roush.com/wp-content/upload ... nsight.pdf

"Damping is the conversion of mechanical energy of a structure into thermal energy"

When you're stretching (and un-stretching) a fly line, a part of the energy is stored as potential energy and another converted into thermal energy.

"A purely elastic material is one in which all the energy stored in the sample during loading is returned when the load is removed."

"A complete opposite to an elastic material is a purely viscous material .. All the energy is lost as “pure damping” once the load is removed."

"For all others that do not fall into one of the above extreme classifications, we call viscoelastic materials."

Now my idea is to measure the "loss" with simple tools: a line sample, a test weight, recording the decay of the oscillations with a smartphone and then determining the damping by video analysis. More about this in one of the next postings.

Torsten.

Bernd has written a nice front page about "Fly Line Stretch"

https://www.sexyloops.com/index.php/ps/fly-line-stretch

and we had already a in-depth discussion at the tackle section here:

https://www.sexyloops.co.uk/theboard/vi ... =18&t=3622

Some fly line companies claim indeed that low-stretch fly lines have several advantages, but to my knowledge no objective studies exist that would prove these claims.

See for instance:

Tim Rajeff explains barstool Line low stretch technology

RIO InTouch Lines with ConnectCore

So I thought it makes sense to create a topic also here in the physics section, where we can collect ideas for measuring fly lines, equations and models. When we have enough information gathered, we should be able to check the plausibility of the above mentioned supposed advantages. Also when we have measured these properties we can insert them into existing fly line models to make them more realistic.

We can find most definitions/equations on Wikipedia, so I'll link/cite these pages.

Properties to characterize fly line stretch

A simple model for the fly line would be a linear spring and stiffness is usually employed to describe their behaviour:

From https://en.wikipedia.org/wiki/Stiffness

"The stiffness, \(k\) of a body is a measure of the resistance offered by an elastic body to deformation."

\(k = \frac {F}{\delta}\)

where

\(F\) is force on the body and

\(\delta\) is the displacement.

Measuring stiffness of a fly line at home:

(1) Mark a section of a fly line at a distance of 1m e.g. with a china marker

(2) Take several test weights and measure the elongation of the fly line between the markers

\(l1\) = 1m

\(l2\) = your measured value

\(k = \frac{m_{test} * 9.81 \frac{m}{s²}}{l_2 - l_1}\)

The guys from the German fly fishing forum used always a 1,8 kg test weight. Here are some of their findings (German term "Dehnungswerte" in the reviews):

https://www.fliegenfischer-forum.de/flischnu.html

Example 5% @ 1,8kg

\(l2 = 1.05m @ 1,8kg\)

\(k = 1.8kg * 9.81 \frac{m}{s²} / (1.1m - 1m) = 353.16N/m\)

Relationship to elasticity

Another possible property would be the elastic modulus (of the fly line material).

https://en.wikipedia.org/wiki/Elastic_modulus

"An elastic modulus (also known as modulus of elasticity) is a quantity that measures an object or substance's resistance to being deformed elastically (i.e., non-permanently) when a stress is applied to it."

https://en.wikipedia.org/wiki/Stiffness

"The elastic modulus of a material is not the same as the stiffness of a component made from that material. Elastic modulus is a property of the constituent material; stiffness is a property of a structure or component of a structure, and hence it is dependent upon various physical dimensions that describe that component. That is, the modulus is an intensive property of the material; stiffness, on the other hand, is an extensive property of the solid body that is dependent on the material and its shape and boundary conditions."

If you know the cross-sectional area, you can compute the elastic modulus from the following equation:

\(E = k * L / A\)

\(A\) is the cross-sectional area

\(L\) is the length of the object

for above example, if we assume a fly line diameter of 1mm:

\(A = \pi * r²\) where r is the fly line radius, thus

\(E = \frac{353,16 N/m * 1m}{\pi * (0.001m / 2)²} = 401274175 N/m² = 0.4 GPa\)

The slight challenge is here, that a fly line consists of multiple materials; the core has a different elastic modulus than the coating. You could assume an average cross-sectional area, but I'd say that choosing the stiffness@1m as property makes more sense.

Viscoelasticity / Damping

Here you will find a good introduction to this topic:

https://www.roush.com/wp-content/upload ... nsight.pdf

"Damping is the conversion of mechanical energy of a structure into thermal energy"

When you're stretching (and un-stretching) a fly line, a part of the energy is stored as potential energy and another converted into thermal energy.

"A purely elastic material is one in which all the energy stored in the sample during loading is returned when the load is removed."

"A complete opposite to an elastic material is a purely viscous material .. All the energy is lost as “pure damping” once the load is removed."

"For all others that do not fall into one of the above extreme classifications, we call viscoelastic materials."

Now my idea is to measure the "loss" with simple tools: a line sample, a test weight, recording the decay of the oscillations with a smartphone and then determining the damping by video analysis. More about this in one of the next postings.

Torsten.

- Paul Arden

- Site Admin

- Posts: 19600

- Joined: Thu Jan 03, 2013 11:20 am

- Location: Belum Rainforest

- Contact:

Re: Fly Line Stretch and Viscoelasticity

Hi Torsten,

I’m very happy to run some tests. We do have the database ready for line weight measurements and if we can have a simple way of measuring stretch (and recovery) then even better.

I have two questions. The first is: I stretch my line before fishing. That’s undoubtedly going to give different results if we stretch first — as many of us would — compared to straight off the reel. What are your thoughts on this? Maybe measure for each?

I would imagine that temperature will make a difference too? But I don’t know how much. Maybe air temperature should be recorded at the time of measuring, since we might find it a useful number later on?

Cheers, Paul

I’m very happy to run some tests. We do have the database ready for line weight measurements and if we can have a simple way of measuring stretch (and recovery) then even better.

I have two questions. The first is: I stretch my line before fishing. That’s undoubtedly going to give different results if we stretch first — as many of us would — compared to straight off the reel. What are your thoughts on this? Maybe measure for each?

I would imagine that temperature will make a difference too? But I don’t know how much. Maybe air temperature should be recorded at the time of measuring, since we might find it a useful number later on?

Cheers, Paul

- gordonjudd

- Posts: 1859

- Joined: Sat Jan 19, 2013 11:36 pm

- Location: Southern California

Re: Fly Line Stretch and Viscoelasticity

Torsten,Some fly line companies claim indeed that low-stretch fly lines have several advantages, but to my knowledge no objective studies exist that would prove these claims.

I don't know how you would prove that the "bungee cord" effect would come into play when casting since the max tension in the line is only a few Newtons at MRF when the force from the rod tip is at its maximum. But maybe good casters could feel a difference between stretchy and stiff lines when casting.

The effect of line stretch when setting a hook was discussed a bit in the other topic, but again but showed that line stretch would only come into play when the hook is set with a haul back of the line with the rod pointing at the fish. If the set was done by lifting the rod then the much lower spring constant of the rod would swamp out any lag that might come from line stretch.

I think that fly lines are at least a cousin to measuring the spring constant of a rubber band where the slope of the force vs. deflection curve would give different sprint constant values for different loads. Thus to compare the characteristics of different lines it will be important to measure them at a specified load such as is done at the German fly fishing forum.

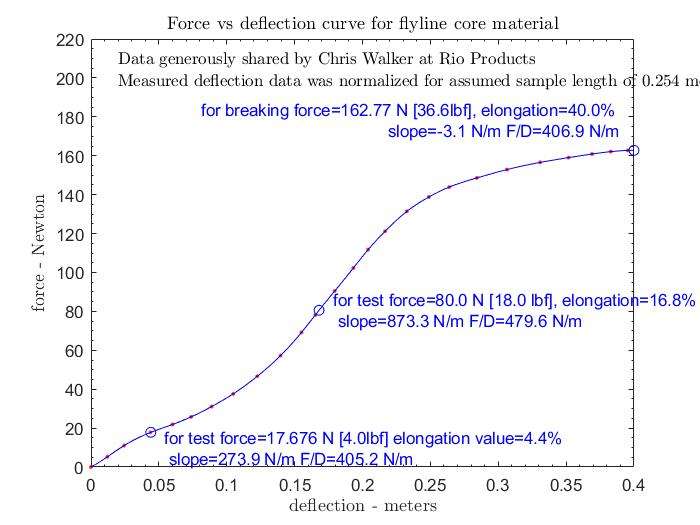

Chris Walker of Rio Products has been kind enough to share an example of the professional measurements they can take on different core materials with their Instron machine. He decided not to use this core material in Rio lines but it shows how much variation there is in the core materials spring constant with different loads. Here is the force vs deflection curve that was obtained on a sample of 30 lb test core material.

You can see this material has a knee in its spring constant near the 17.6 N test point used to characterize the elongation value. At that point the elongation value was 4.4% even though its spring constant softened to produce a a 40% stretch value just before it broke. The high stretch at the breaking point is what Simeon Gawesworth and Tim Rajeff are referring to in their video clips. The stretch would be much much less for the line tension produced in casting.

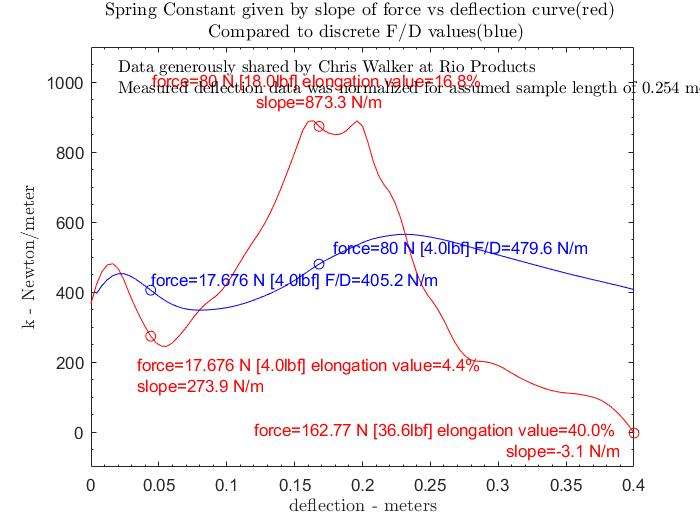

The localized spring constant of the line is related to the slope of the force vs deflection curve as shown below:

It varied over a 3:1 range for this core material. Thus we can expect much different spring constant values ( red curve) depending on the test load. Fortunately the discrete force/deflection values shown in blue curve tend to be around 420 N/m over the full test range.

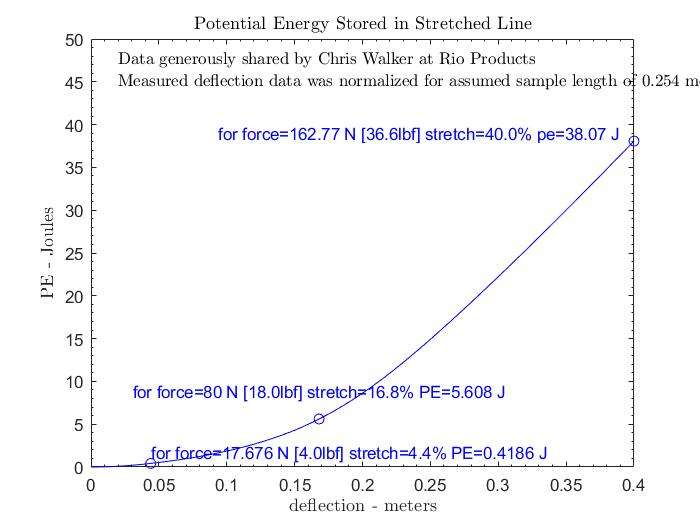

The spring energy in the line is related to the area under the F/D curve as shown below.

For the range of line tension produced by acceleration forces when casting the expected energy loss due to line stretch would be very low. Even for the 17.6 N force used to determined the elongation value the potential energy resulting from the stretch in the line would be less than a Joule.

Gordy

Re: Fly Line Stretch and Viscoelasticity

Gordy,

For all intents and purposes Instron testing is effectively a static test. This is why we need a DMA in order to get a dynamic result in a suitable frequency domain (I will run a DMA test next time I visit my lab). As such, I'd question the validity of your energy loss conclusions as you've applied static measurements to a dynamic problem.

James

For all intents and purposes Instron testing is effectively a static test. This is why we need a DMA in order to get a dynamic result in a suitable frequency domain (I will run a DMA test next time I visit my lab). As such, I'd question the validity of your energy loss conclusions as you've applied static measurements to a dynamic problem.

James

- gordonjudd

- Posts: 1859

- Joined: Sat Jan 19, 2013 11:36 pm

- Location: Southern California

Re: Fly Line Stretch and Viscoelasticity

Paul,That’s undoubtedly going to give different results if we stretch first — as many of us would — compared to straight off the reel.

You have touched on an important factor. Being a viscoelastic material, Fly lines will have considerable hysteresis when you measure their force vs deflection characteristics. Worse yet they will tend to show creep for higher loads and thus the deflection for higher forces will change during the measurement. Thus it becomes a judgement call on what deflection to use for a given load since so the stretch you get will depend on the time it takes for the creep to stabilize.

This article highlights some of the problems involved with trying to measure the spring constant of a rubber band. I would expect you will see similar hysteresis effects (difference in the f/d characteristic for increasing and decreasing loads) in a length of fly line as he recorded with his automated measurements. You will find that a line will show some residual stretch and thus will not returns to the same zero load value after it has been subjected to a high load as shown for the rubber band below. It will be interesting to see if James runs into similar problems with his DMA measurements, i.e. getting different results when measurements are repeated back to back.

Gordy

Re: Fly Line Stretch and Viscoelasticity

Gordy,gordonjudd wrote: ↑Fri Nov 19, 2021 7:20 pm It will be interesting to see if James runs into similar problems with his DMA measurements, i.e. getting different results when measurements are repeated back to back.

Gordy

I think you might be misinterpreting what the DMA measures. In your load/unload test on a rubber band above, the area described between the loading and unloading cycles (i.e. the hysteresis) is proportional to the mechanical loss. The DMA measures this loss by performing multiple load/unload cycles. There are two main operational modes - frequency sweep where the frequency of the load/unload cycles is varied between the user defined limits; and Temperature sweep where the frequency is fixed (usually to avoid any harmonics) and the temperature is ramped. You can of course build a parameter map by by performing multiple frequency scans at different temperature steps.

How the equipment works is to apply a static loading, and then on top of that a dynamic loading is cycled (for which the frequency is controlled). The mechanical response of the sample (the force, displacement etc.) is sampled at high speed within each cycle. Thus any lag (hysteresis) in the unloading caused by the viscoelastic properties is measured against the phase angle of the applied input. Therefore I'll be certain to see the effect of the load/unload hysteresis - that's the whole point.

James

- gordonjudd

- Posts: 1859

- Joined: Sat Jan 19, 2013 11:36 pm

- Location: Southern California

Re: Fly Line Stretch and Viscoelasticity

James,Therefore I'll be certain to see the effect of the load/unload hysteresis - that's the whole point.

I realize that you will be able to measure the hysteresis. The point I was trying to make is because of creep (amount of deflection changes for a large load) that the hysteresis you get with one set of DMA measurements will be different than the hysteresis you get for a second set of measurements taken after the line has be subjected to a large load, i.e.

I have found that making force vs deflection measurements on a long length of line are frustrating to do since the repeatability is so bad. People doing those tests will find line does not return to the same zero force length after it has been stretched by a large load. Worse yet, the deflection to use for a new large load is also a moving target because of creep.It will be interesting to see if James runs into similar problems with his DMA measurements, i.e. getting different results when measurements are repeated back to back.

How would you answer Paul's pertinent question about trying to accurately measure the stretch in lines.

I have two questions. The first is: I stretch my line before fishing. That’s undoubtedly going to give different results if we stretch first — as many of us would — compared to straight off the reel. What are your thoughts on this? Maybe measure for each?

Gordy

Re: Fly Line Stretch and Viscoelasticity

Gordy,gordonjudd wrote: ↑Sat Nov 20, 2021 2:53 pm The point I was trying to make is because of creep (amount of deflection changes for a large load) that the hysteresis you get with one set of DMA measurements will be different than the hysteresis you get for a second set of measurements taken after the line has be subjected to a large load,

Gordy

You're getting your terms a bit muddled here; creep is a time dependant process. What you're describing is a plastic deformation arising from the large applied load.

Without knowing the timings on the the example elastic band response you posted it's impossible to know which process is at play, or which dominates. Note, the recovery from straining in a viscoelastic material can take a long time so you'd need to know whether the extension (without load) was monitored for several minutes at the end of the test to see if the original dimension was recovered.

If you stretch a line and it retains a 'set' i.e. a permanent extension, then the subsequent viscoelastic properties are unlikely to change that much. This is because the viscoelastic properties are fundamental to the material and its chemistry, not so much its strain history. The straight elastic properties might well change however - I would expect the line to demonstrate a higher Young's modulus.

James

Re: Fly Line Stretch and Viscoelasticity

Hi James,

Paul:

"In physics and materials science, plasticity, also known as plastic deformation, is the ability of a solid material to undergo permanent deformation, a non-reversible change of shape in response to applied forces."

https://en.wikipedia.org/wiki/Plasticity_(physics)

For a database I'd keep it simple and choose what's closest to the actual usage of the line, that means prestretching the line. For the temperature usually you would measure also at the extremes, but I think if nothing is specified I'd choose room temperature (and record the temperature).

Thanks,

Torsten

I think he means the elastic energy and not the "loss"; and that is for his example indeed pretty small. What frequency range will you use?This is why we need a DMA in order to get a dynamic result in a suitable frequency domain (I will run a DMA test next time I visit my lab). As such, I'd question the validity of your energy loss conclusions as you've applied static measurements to a dynamic problem.

Paul:

James has mentioned it; plasticity might play a role:I have two questions. The first is: I stretch my line before fishing. That’s undoubtedly going to give different results if we stretch first — as many of us would — compared to straight off the reel. What are your thoughts on this? Maybe measure for each?

I would imagine that temperature will make a difference too? But I don’t know how much. Maybe air temperature should be recorded at the time of measuring, since we might find it a useful number later on?

"In physics and materials science, plasticity, also known as plastic deformation, is the ability of a solid material to undergo permanent deformation, a non-reversible change of shape in response to applied forces."

https://en.wikipedia.org/wiki/Plasticity_(physics)

For a database I'd keep it simple and choose what's closest to the actual usage of the line, that means prestretching the line. For the temperature usually you would measure also at the extremes, but I think if nothing is specified I'd choose room temperature (and record the temperature).

Thanks,

Torsten

- gordonjudd

- Posts: 1859

- Joined: Sat Jan 19, 2013 11:36 pm

- Location: Southern California

Re: Fly Line Stretch and Viscoelasticity

James,You're getting your terms a bit muddled here; creep is a time dependant process

Exactly. At some point the deformation will continue to change for a fixed load, which makes it difficult to pick a deflection value for a new load.

No doubt there is some permanent plastic deformation taking place as well and that is why the hysteresis loop does not close.

All said and done I have found taking force vs deflection data on a flyline to be much more complicated than it is for a fly rod. I hope your DMA measurements will be more repeatable.

Gordy