I’m not sure to follow the logic of Jack Moray : where do the guideline curves come from? A best guess? Something theoretical?

Merlin,

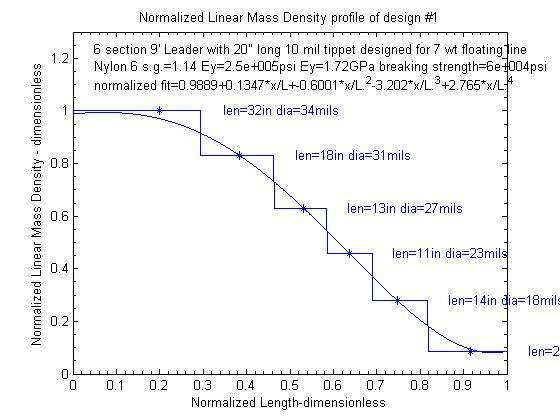

I think his normalized curve shape came from experience. As I said in order to get section lengths that matched up with his examples I had to use the "experience-based" normalized curve rather than strictly following the iteration procedure he spelled out in his method. He was doing his calculations with a calculator and graph paper, so cutting corners on calculations might have been a practical necessity. Also he may have found that to get a better lay out of the fly he lengthened the section lengths of the tippet end of the leader to eliminate the splash down effect when fishing dry flies.

Good tournament casters will lengthen (or shorten) the tippet on their dry fly leaders to get the fly to "hover" over the ring at the end of the cast so that they can better judge distance. A 1-2" difference in tippet length will make a big difference in how the fly hovers for them, but I was never that sophisticated. Thanks to John Napoli at the Long Beach Casting Club for showing me that adjustment trick many years ago.

I would expect that based on practical experience Jack Moray used different normalized curve shapes for different situations as well. I have noticed that Rajeff's Bass Bug leader design has a convex slope from beginning to end to get a good turn over of the bug. Harvey used a S-shaped curve with longer flatter transitions at the tippet end. That tends to produce wiggles in the layout of a long leader to help reduce the drag on dry flies. I expect Moray did the same thing, i.e. developed different normalized rho_l vs distance curves for different types of fishing situations. John may have some examples of the different curves he used.

Since leader density is a constant (if you don't mix materials), then I cant' see impedance conservation here.

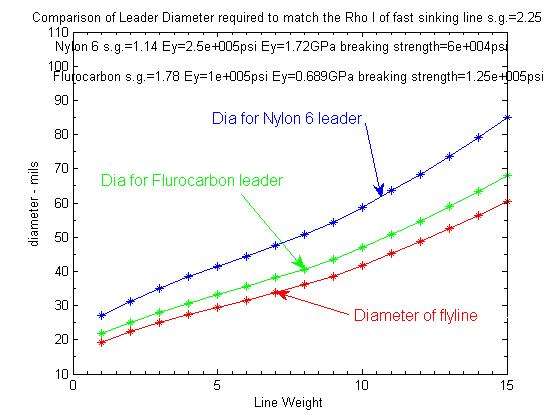

If you assume the velocity of the wave at the boundaries is the same and knowing that the Tension is proportional to rho_l*v.^2 then the impedance will change whenever you change the linear mass density as shown below.

http://img12.imageshack.us/img12/6982/impedanceequation.jpg

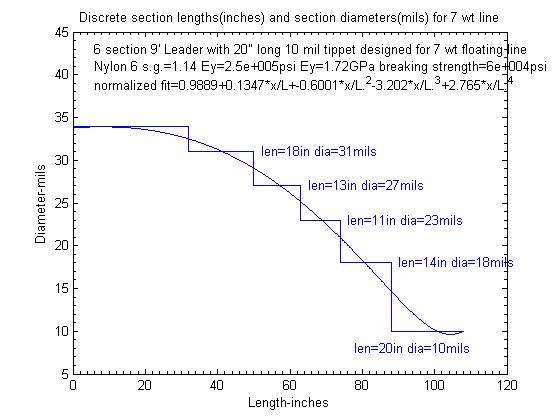

Thus the relative impedance for two adjacent sections will be proportional to their rho_l values which will be proportional to the square of their diameters for a leader made with the same material.

Moray's point was it is better to have a series of nominally equal impedance ratios in each of the transmission loss values rather than having big losses that would result from big impedance ratio differences at the butt end of the leader followed by smaller impedance ratios as you get to the tippet end of the leader.

That approach is in keeping with the guideline given in the

Harvard transverse wave paper where the emphasis is on the gradual change in the impedance difference between each section.

The two basic ways to match two impedances are to (1) simply make one of them equal

to the other, or (2) keep them as they are, but insert a large number of things (whatever

type of things the two original ones are) between them with impedances that gradually

change from one to the other.

Since the linear mass density varies as the square of the diameter that means you have smaller diameter steps at the butt end of the leader than you do at the tippet end. That logic makes some sense to me, and is counter to the prescription given in most leader formulas where the big steps are at the butt end followed by smaller steps at the tippet end.

OK, I'm not going to open an issue on "COI" (conservation of inpedance), it is just to understand the logic behind.

You can breathe a sigh of relief. Just as COM does not apply to the predicting the fly velocity history in a normal tethered cast, there is no COI going on with Moray's leader design approach either.

Gordy